(carbon fiber concrete)

Carbon Fiber Concrete: Enhancing Structural Performance Through Advanced Reinforcement

Carbon fiber concrete represents a significant advancement in construction materials, offering superior strength, durability, and design flexibility compared to traditional reinforced concrete.

1. What Is Carbon Fiber Concrete?

1.1 Definition and Composition

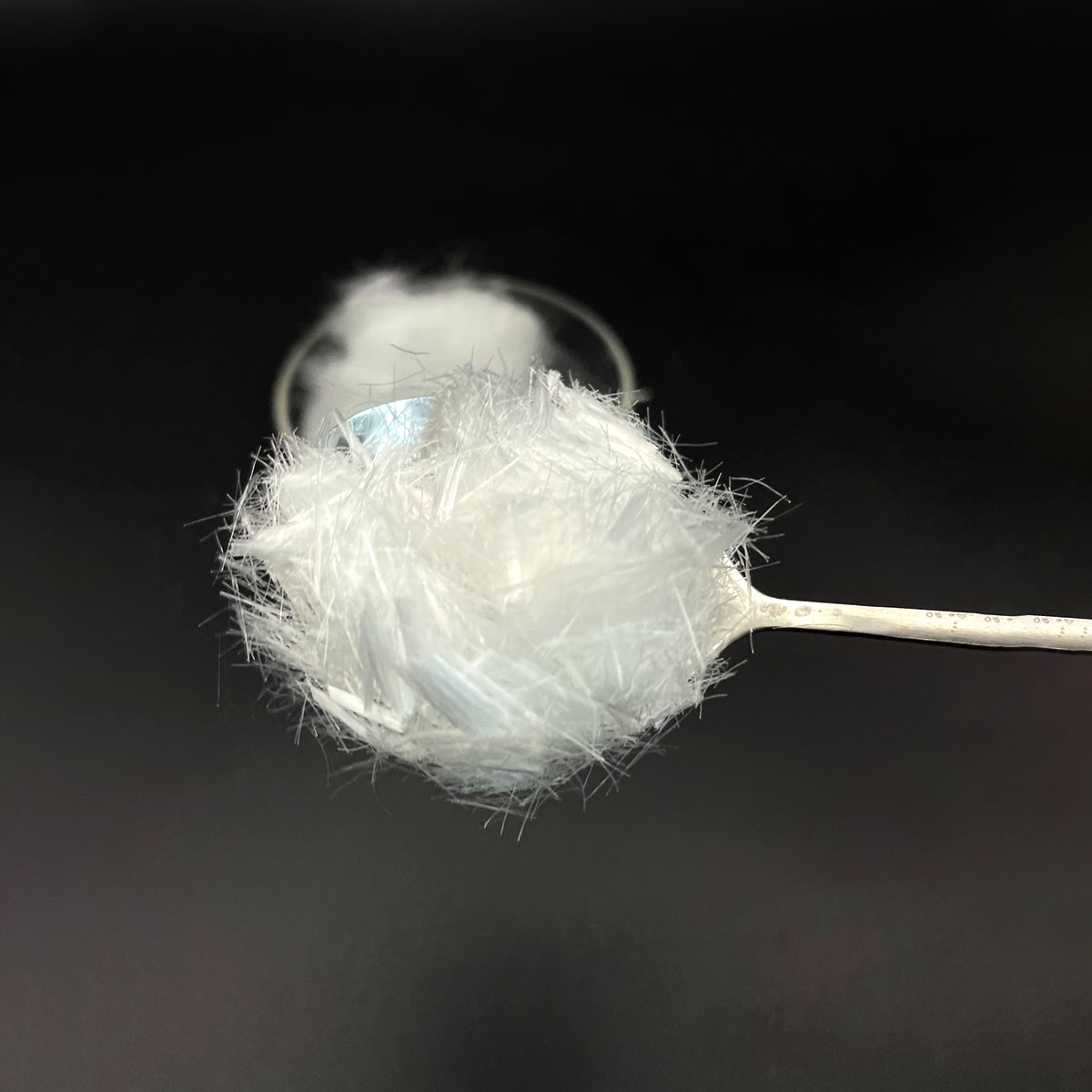

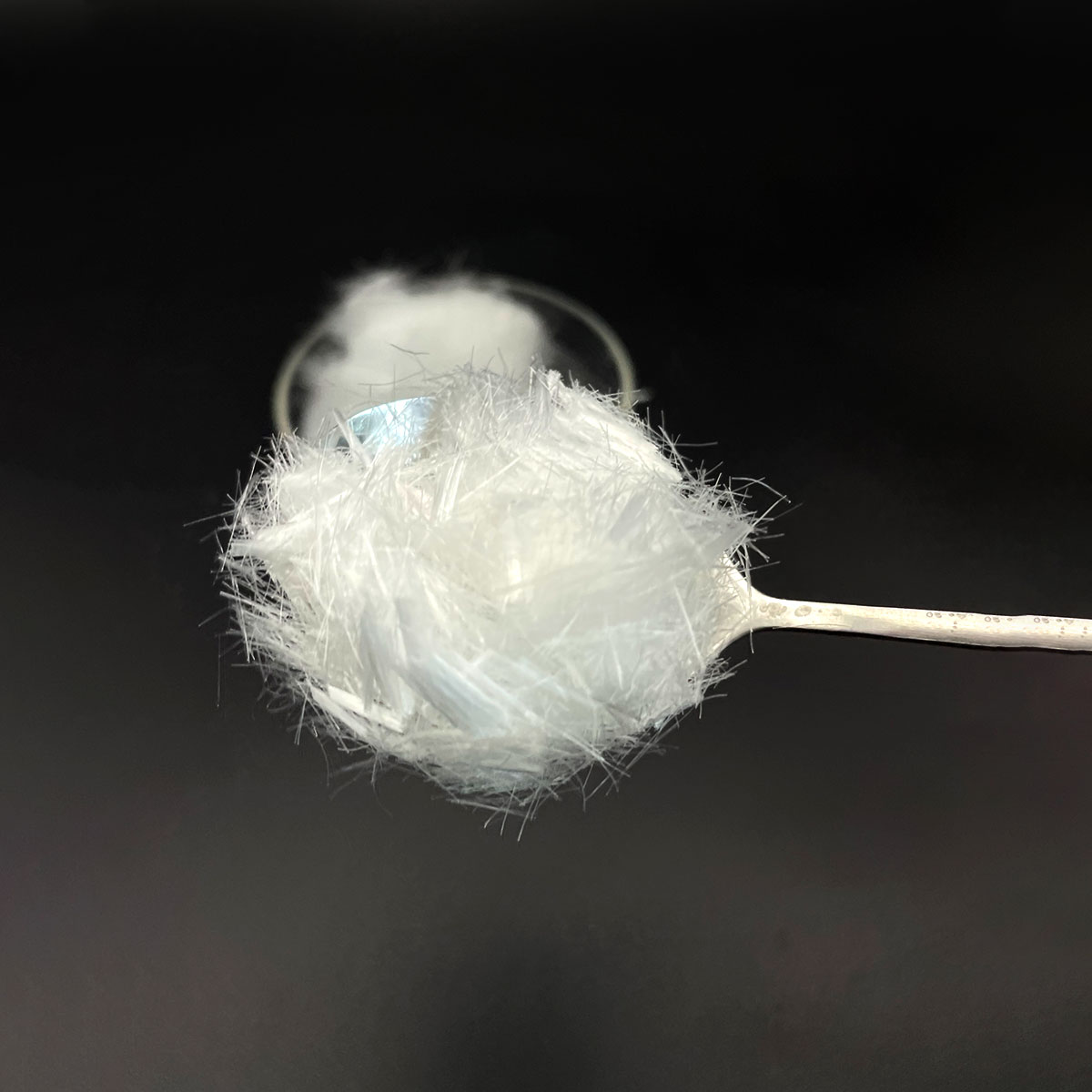

Carbon fiber concrete, also known as carbon fiber reinforced concrete (CFRC), is a composite material where carbon fibers are incorporated into the concrete matrix to enhance its mechanical properties. Unlike traditional steel-reinforced concrete, CFRC utilizes high-strength carbon filaments that are either randomly distributed or arranged in specific orientations within the mix. These fibers typically range from 5 to 20 microns in diameter and are added in volumes between 0.5% to 2% of the total concrete mass. The material combines the compressive strength of concrete with the exceptional tensile strength of carbon fibers, creating a synergistic effect that significantly improves structural performance while reducing weight.

1.2 Distinguishing Features

Carbon fiber concrete distinguishes itself from other fiber-reinforced concretes through its unique combination of properties. The carbon fibers offer substantially higher tensile strength (up to 4,000 MPa) compared to glass or polypropylene fibers, while maintaining exceptional chemical resistance. Unlike steel reinforcement, carbon fibers are non-corrosive, eliminating a major durability concern in concrete structures. The material also exhibits electromagnetic neutrality, making it suitable for sensitive applications where metal reinforcement would cause interference. Furthermore, carbon fiber’;s thermal expansion coefficient closely matches that of concrete, reducing thermal stress issues common in traditional reinforced concrete.

2. Why Carbon Fiber Concrete Has Good Characteristics

2.1 Enhanced Mechanical Properties

Carbon fiber concrete demonstrates superior mechanical characteristics due to the exceptional tensile strength and modulus of elasticity of carbon fibers. When incorporated into the concrete matrix, these fibers bridge microcracks that form during the curing process and under load, significantly improving flexural strength (up to 300% increase) and fracture toughness. The high stiffness of carbon fibers (200-800 GPa) provides effective crack control, reducing crack widths and slowing propagation. This results in improved fatigue resistance and impact strength, making CFRC particularly valuable in seismic applications and structures subject to dynamic loads. The material maintains its integrity even after initial cracking, exhibiting pseudo-ductile behavior rather than sudden brittle failure.

2.2 Superior Durability and Longevity

The durability advantages of carbon fiber concrete stem primarily from the non-corrosive nature of carbon fibers and their chemical inertness. Traditional steel reinforcement corrosion accounts for approximately 90% of concrete deterioration worldwide, but carbon fibers eliminate this failure mechanism entirely. CFRC demonstrates exceptional resistance to chloride ion penetration, sulfate attack, and freeze-thaw cycles. The material’;s reduced permeability minimizes moisture ingress and associated deterioration mechanisms. Additionally, carbon fibers maintain their properties in extreme temperatures (-200°C to +650°C) without significant degradation. These characteristics contribute to significantly extended service life with reduced maintenance requirements, particularly in aggressive environments like marine structures, industrial facilities, and deicing salt-exposed infrastructure.

3. How Carbon Fiber Concrete Is Produced

3.1 Material Selection and Preparation

Producing high-quality carbon fiber concrete begins with careful material selection. The carbon fibers typically used are polyacrylonitrile (PAN)-based with lengths ranging from 6mm to 30mm for dispersed reinforcement, or continuous strands for specific applications. The concrete mix design requires optimization to ensure proper fiber dispersion and workability. Key considerations include using well-graded aggregates, appropriate cement content, and specialized fiber reinforced concrete mix design principles to balance rheology with fiber content. Water-reducing admixtures are essential to maintain low water-cement ratios while ensuring adequate workability for proper consolidation around the fibers.

3.2 Mixing and Placement Techniques

The production process for carbon fiber concrete requires specialized mixing techniques to ensure uniform fiber distribution without balling or segregation. Typically, fibers are added after initial mixing of other components, either through controlled dispersion systems or pre-mixed in specialized admixtures. Mixing duration is critical –; insufficient mixing leads to poor dispersion, while excessive mixing can damage fibers. Placement methods vary depending on application: conventional pouring for slabs, extrusion for precast elements, or spray application for repairs and thin sections. Proper consolidation using vibration must balance fiber alignment with air removal, avoiding excessive vibration that may cause fiber segregation. Curing follows standard concrete practices but with particular attention to moisture control during early stages to prevent plastic shrinkage cracking.

4. Application Fields of Carbon Fiber Concrete

4.1 Infrastructure and Transportation

Carbon fiber concrete finds extensive application in transportation infrastructure where durability and weight reduction are critical. Bridge decks benefit from CFRC’;s corrosion resistance, particularly in areas with deicing salts, extending service life while reducing maintenance costs. The material’;s high strength-to-weight ratio enables longer span lengths and slimmer profiles in bridge construction. Tunnel linings utilize CFRC for its crack resistance and durability in wet environments. In pavement applications, carbon fiber reinforcement improves fatigue resistance at joints and cracks, extending pavement life. Additionally, CFRC is increasingly used in modern construction of sound barriers and retaining walls where its durability and reduced maintenance requirements offer lifecycle cost advantages.

4.2 Building Construction and Specialized Structures

In building construction, carbon fiber concrete enables innovative architectural designs through its combination of strength and formability. Thin structural elements like façade panels, sunscreens, and architectural cladding benefit from CFRC’;s high tensile strength and reduced thickness requirements. Seismic-resistant structures utilize carbon fiber’;s energy absorption capabilities for improved performance during earthquakes. The material is particularly valuable in high-rise construction where weight reduction decreases foundation requirements and enables taller designs. Specialized applications include blast-resistant structures, electromagnetic-sensitive facilities (research labs, hospitals), and industrial structures exposed to corrosive chemicals. Additionally, CFRC is revolutionizing repair and strengthening applications through carbon fiber reinforced polymer (CFRP) systems applied to existing structures, offering a non-invasive solution for enhancing concrete durability.

5. How To Choose Good Carbon Fiber Concrete

5.1 Performance-Based Selection Criteria

Selecting quality carbon fiber concrete requires evaluating multiple performance parameters based on application requirements. Key mechanical properties to consider include flexural strength (typically 8-25 MPa), compressive strength (40-100 MPa), and post-cracking behavior. Durability indicators such as chloride diffusion coefficient, freeze-thaw resistance, and abrasion resistance should meet project-specific environmental exposure requirements. For structural applications, verify modulus of elasticity (typically 30-50 GPa) and creep characteristics. Workability parameters must align with placement methods –; slump for pouring applications or extrudability for precast production. Additionally, consider long-term performance metrics like shrinkage characteristics and bond strength with conventional concrete if used in composite applications.

5.2 Material Specification and Quality Assurance

Effective specification of carbon fiber concrete involves detailed technical requirements for both fiber properties and concrete performance. Fiber specifications should include tensile strength (>3,500 MPa), modulus of elasticity (>200 GPa), fiber length (typically 12-24mm), and surface treatment for optimal bonding. Concrete mix parameters must specify maximum water-cement ratio (typically 0.40-0.45), minimum cement content (350-450 kg/m³), and admixture requirements. Quality assurance protocols should include batch testing for fiber dispersion uniformity, air content, and fresh concrete density. Hardened concrete testing should verify mechanical properties and durability characteristics through standardized test methods. For critical applications, consider performance-based specifications with durability index testing to ensure long-term strength and durability.

6. What People Also Ask About Carbon Fiber Concrete

6.1 Cost and Practical Implementation Questions

Common inquiries about carbon fiber concrete often focus on economic and practical aspects. People frequently ask about cost comparison with traditional reinforced concrete –; while CFRC has higher initial material costs (approximately 2-3 times), lifecycle cost analysis typically shows advantages through reduced maintenance and extended service life. Another frequent question concerns installation differences –; CFRC generally uses similar placement equipment but requires specialized mixing procedures and worker training. People inquire about compatibility with conventional reinforcement systems; CFRC can be used in hybrid systems but requires careful electrochemical compatibility assessment. Other common questions address fire performance (carbon fibers lose strength around 400°C but don’;t melt), recycling potential (developing technologies for fiber recovery), and comparative environmental impact (higher embodied energy but potentially lower lifecycle impact).

6.2 Technical Performance and Application Questions

Technical questions about carbon fiber concrete often focus on performance characteristics and limitations. Many ask about crack control effectiveness –; CFRC significantly reduces crack widths but doesn’;t eliminate cracking entirely. Common inquiries address bond characteristics with existing concrete in repair applications, which is excellent when proper surface preparation is performed. People question electrical conductivity –; while carbon fibers are conductive, properly dispersed CFRC remains non-conductive due to the insulating concrete matrix. Other frequent questions concern long-term behavior, particularly creep characteristics (similar to conventional concrete) and UV resistance (carbon fibers require protection in exposed applications). Designers often inquire about structural design approaches, which typically combine conventional concrete design principles with modified tension-stiffening models to account for fiber contribution.

Tags: carbon fiber reinforced concrete, CFRC, carbon fiber concrete mix, concrete reinforcement fibers, structural concrete fibers, carbon fiber mesh concrete, high-performance concrete, concrete durability solutions, fiber concrete admixtures

(carbon fiber concrete)

Supplier

Mis-Asia is committed to technology development, applications of nanotechnology, and new material industries, with professional experience in nanotechnology research and development and the application of materials. As a leading manufacturer of nanotechnology development and product applications, we offer solutions for every process and step in the laboratory and industry. Our professional work team provides the perfect solutions to help industries improve efficiency, create value, and easily meet challenges.