Intro to Hollow Glass Microspheres

Hollow glass microspheres (HGMs) are hollow, spherical particles typically fabricated from silica-based or borosilicate glass materials, with sizes generally varying from 10 to 300 micrometers. These microstructures show an one-of-a-kind combination of low density, high mechanical stamina, thermal insulation, and chemical resistance, making them extremely versatile throughout multiple industrial and scientific domains. Their production involves accurate design methods that permit control over morphology, shell thickness, and internal void volume, enabling customized applications in aerospace, biomedical engineering, energy systems, and a lot more. This short article supplies a detailed review of the major techniques utilized for producing hollow glass microspheres and highlights 5 groundbreaking applications that highlight their transformative potential in contemporary technological developments.

(Hollow glass microspheres)

Manufacturing Approaches of Hollow Glass Microspheres

The construction of hollow glass microspheres can be extensively categorized right into 3 main methods: sol-gel synthesis, spray drying, and emulsion-templating. Each method offers unique advantages in regards to scalability, bit uniformity, and compositional adaptability, allowing for personalization based upon end-use needs.

The sol-gel procedure is one of one of the most commonly utilized techniques for producing hollow microspheres with precisely regulated architecture. In this approach, a sacrificial core–; commonly composed of polymer grains or gas bubbles–; is coated with a silica precursor gel via hydrolysis and condensation reactions. Succeeding heat treatment gets rid of the core material while compressing the glass covering, resulting in a durable hollow structure. This method enables fine-tuning of porosity, wall density, and surface chemistry but typically requires complex reaction kinetics and extended handling times.

An industrially scalable alternative is the spray drying method, which includes atomizing a fluid feedstock having glass-forming forerunners into great droplets, complied with by rapid evaporation and thermal decomposition within a heated chamber. By integrating blowing representatives or lathering compounds into the feedstock, internal voids can be produced, causing the development of hollow microspheres. Although this technique enables high-volume production, attaining consistent covering densities and decreasing flaws continue to be recurring technical challenges.

A third appealing technique is emulsion templating, wherein monodisperse water-in-oil solutions act as templates for the development of hollow frameworks. Silica forerunners are concentrated at the user interface of the solution droplets, creating a thin covering around the liquid core. Following calcination or solvent removal, distinct hollow microspheres are acquired. This approach excels in generating particles with slim dimension circulations and tunable functionalities but necessitates cautious optimization of surfactant systems and interfacial problems.

Each of these manufacturing methods contributes distinctly to the style and application of hollow glass microspheres, providing designers and researchers the devices needed to tailor buildings for innovative practical materials.

Wonderful Usage 1: Lightweight Structural Composites in Aerospace Design

One of one of the most impactful applications of hollow glass microspheres hinges on their use as strengthening fillers in lightweight composite products made for aerospace applications. When integrated into polymer matrices such as epoxy resins or polyurethanes, HGMs substantially lower total weight while keeping architectural integrity under severe mechanical lots. This particular is particularly advantageous in airplane panels, rocket fairings, and satellite elements, where mass performance straight affects gas usage and haul capability.

Additionally, the spherical geometry of HGMs improves stress circulation across the matrix, consequently boosting fatigue resistance and effect absorption. Advanced syntactic foams containing hollow glass microspheres have actually demonstrated exceptional mechanical efficiency in both static and vibrant filling conditions, making them suitable prospects for usage in spacecraft thermal barrier and submarine buoyancy components. Ongoing research continues to explore hybrid compounds incorporating carbon nanotubes or graphene layers with HGMs to further boost mechanical and thermal properties.

Enchanting Usage 2: Thermal Insulation in Cryogenic Storage Systems

Hollow glass microspheres have inherently low thermal conductivity due to the visibility of an enclosed air cavity and very little convective warmth transfer. This makes them incredibly effective as insulating agents in cryogenic atmospheres such as liquid hydrogen containers, dissolved gas (LNG) containers, and superconducting magnets made use of in magnetic vibration imaging (MRI) machines.

When installed right into vacuum-insulated panels or applied as aerogel-based finishings, HGMs act as effective thermal obstacles by decreasing radiative, conductive, and convective warmth transfer devices. Surface alterations, such as silane therapies or nanoporous layers, further boost hydrophobicity and protect against moisture ingress, which is crucial for maintaining insulation efficiency at ultra-low temperature levels. The integration of HGMs right into next-generation cryogenic insulation materials stands for a vital advancement in energy-efficient storage space and transportation options for tidy gas and space expedition modern technologies.

Wonderful Usage 3: Targeted Medicine Delivery and Medical Imaging Contrast Agents

In the field of biomedicine, hollow glass microspheres have actually become encouraging platforms for targeted medication delivery and diagnostic imaging. Functionalized HGMs can encapsulate healing agents within their hollow cores and release them in feedback to exterior stimulations such as ultrasound, magnetic fields, or pH modifications. This ability makes it possible for local therapy of illness like cancer cells, where precision and decreased systemic poisoning are necessary.

Furthermore, HGMs can be doped with contrast-enhancing elements such as gadolinium, iodine, or fluorescent dyes to work as multimodal imaging agents suitable with MRI, CT scans, and optical imaging techniques. Their biocompatibility and ability to carry both therapeutic and diagnostic features make them eye-catching prospects for theranostic applications–; where diagnosis and therapy are integrated within a single platform. Research initiatives are additionally discovering naturally degradable variants of HGMs to expand their energy in regenerative medicine and implantable tools.

Wonderful Usage 4: Radiation Shielding in Spacecraft and Nuclear Infrastructure

Radiation protecting is a critical issue in deep-space objectives and nuclear power centers, where exposure to gamma rays and neutron radiation poses considerable threats. Hollow glass microspheres doped with high atomic number (Z) aspects such as lead, tungsten, or barium supply a novel remedy by offering reliable radiation attenuation without including excessive mass.

By embedding these microspheres right into polymer composites or ceramic matrices, scientists have created flexible, lightweight securing products ideal for astronaut fits, lunar habitats, and reactor containment frameworks. Unlike conventional shielding materials like lead or concrete, HGM-based compounds keep architectural integrity while providing improved mobility and ease of manufacture. Proceeded advancements in doping methods and composite layout are expected to further optimize the radiation security capabilities of these materials for future space exploration and earthbound nuclear safety and security applications.

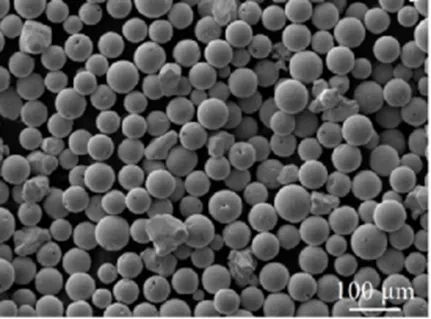

( Hollow glass microspheres)

Magical Use 5: Smart Coatings and Self-Healing Products

Hollow glass microspheres have actually transformed the development of smart coverings with the ability of self-governing self-repair. These microspheres can be loaded with healing representatives such as rust preventions, resins, or antimicrobial compounds. Upon mechanical damage, the microspheres rupture, releasing the encapsulated materials to secure fractures and bring back covering honesty.

This innovation has actually found useful applications in aquatic layers, vehicle paints, and aerospace parts, where long-lasting sturdiness under harsh environmental problems is essential. Additionally, phase-change products encapsulated within HGMs make it possible for temperature-regulating coverings that provide passive thermal management in buildings, electronic devices, and wearable devices. As research progresses, the assimilation of responsive polymers and multi-functional additives into HGM-based coatings guarantees to unlock new generations of adaptive and intelligent product systems.

Conclusion

Hollow glass microspheres exhibit the merging of advanced products science and multifunctional design. Their varied production methods make it possible for specific control over physical and chemical homes, facilitating their use in high-performance structural composites, thermal insulation, clinical diagnostics, radiation defense, and self-healing products. As innovations remain to emerge, the “;enchanting”; convenience of hollow glass microspheres will unquestionably drive breakthroughs throughout markets, forming the future of sustainable and intelligent product style.

Supplier

RBOSCHCO is a trusted global chemical material supplier &; manufacturer with over 12 years experience in providing super high-quality chemicals and Nanomaterials. The company export to many countries, such as USA, Canada, Europe, UAE, South Africa,Tanzania,Kenya,Egypt,Nigeria,Cameroon,Uganda,Turkey,Mexico,Azerbaijan,Belgium,Cyprus,Czech Republic, Brazil, Chile, Argentina, Dubai, Japan, Korea, Vietnam, Thailand, Malaysia, Indonesia, Australia,Germany, France, Italy, Portugal etc. As a leading nanotechnology development manufacturer, RBOSCHCO dominates the market. Our professional work team provides perfect solutions to help improve the efficiency of various industries, create value, and easily cope with various challenges. If you are looking for hollow microspheres, please send an email to: [email protected]

Tags: Hollow glass microspheres, Hollow glass microspheres

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us