Intro to Concrete Foaming Brokers

Concrete foaming representatives are chemical admixtures utilized to generate secure, uniform air gaps within concrete mixtures, leading to lightweight mobile concrete with enhanced thermal insulation, decreased density, and improved workability. These representatives operate by minimizing the surface area stress of blending water, permitting air to be entrained and maintained in the type of discrete bubbles throughout the cementitious matrix. The top quality and efficiency of foamed concrete–; such as its compressive toughness, thermal conductivity, and durability–; are greatly affected by the kind, dosage, and compatibility of the lathering representative used. This short article checks out the devices behind frothing agents, their classification, and exactly how they add to maximizing the residential properties of light-weight concrete for contemporary construction applications.

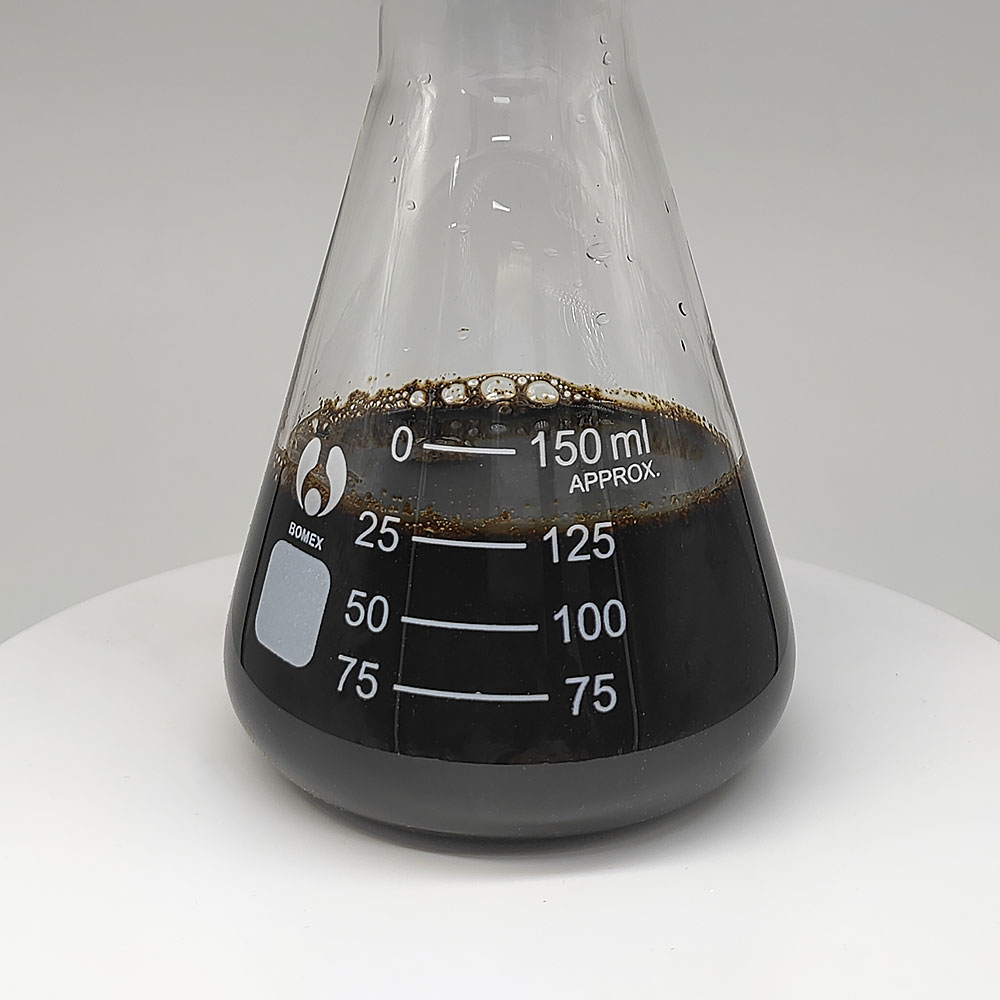

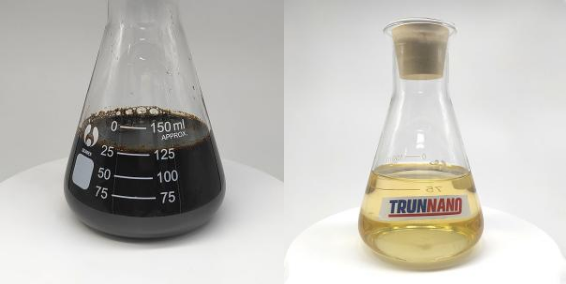

(CLC Foaming Agent)

Category and Mechanism of Concrete Foaming Brokers

Concrete foaming agents can be extensively classified into two main categories: anionic and cationic surfactants, with some non-ionic or amphoteric kinds additionally being employed depending upon specific formula requirements. Anionic lathering agents, such as alkyl sulfates and protein-based hydrolysates, are extensively used because of their exceptional foam stability and compatibility with concrete chemistry. Cationic representatives, although much less common, deal one-of-a-kind advantages in specialized formulations where electrostatic communications need to be managed.

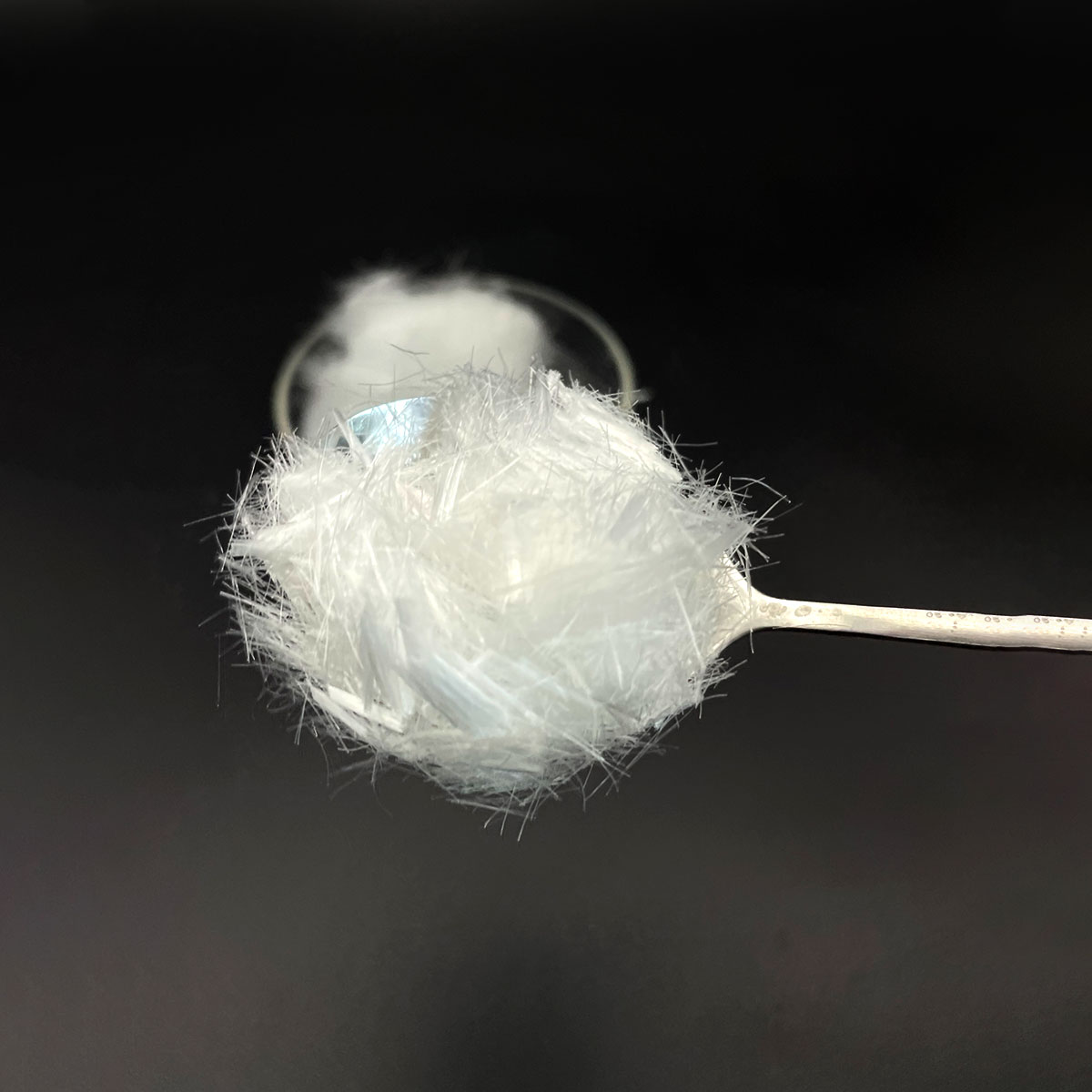

The system of activity includes the adsorption of surfactant particles at the air-water interface, lowering surface area tension and allowing the formation of penalty, steady bubbles during mechanical anxiety. A high-quality lathering representative has to not just generate a big volume of foam yet likewise keep bubble honesty with time to prevent collapse before concrete hydration is full. This calls for a balance in between foaming capability, drain resistance, and bubble coalescence control. Advanced formulations typically incorporate stabilizers such as viscosity modifiers or polymers to enhance bubble perseverance and boost the rheological habits of the fresh mix.

Effect of Foaming Professionals on Lightweight Concrete Quality

The intro of air gaps with foaming representatives substantially changes the physical and mechanical features of light-weight concrete. By changing strong mass with air, these gaps decrease general density, which is especially valuable in applications calling for thermal insulation, audio absorption, and architectural weight decrease. For instance, frothed concrete with thickness ranging from 300 to 1600 kg/m ³ can attain compressive staminas between 0.5 MPa and 15 MPa, relying on foam content, cement kind, and healing problems.

Thermal conductivity decreases proportionally with enhancing porosity, making foamed concrete an eye-catching alternative for energy-efficient building envelopes. Furthermore, the visibility of evenly dispersed air bubbles boosts freeze-thaw resistance by acting as stress relief chambers throughout ice expansion. Nonetheless, excessive lathering can lead to weak interfacial shift areas and bad bond development between cement paste and accumulations, potentially compromising long-lasting durability. Consequently, specific dosing and foam quality assurance are vital to attaining optimum efficiency.

Optimization Strategies for Boosted Efficiency

To maximize the advantages of foaming agents in lightweight concrete, a number of optimization strategies can be used. First, picking the ideal foaming agent based upon basic materials and application needs is critical. Protein-based representatives, as an example, are liked for high-strength applications because of their premium foam stability and compatibility with Portland concrete. Artificial surfactants might be preferable for ultra-lightweight systems where lower expenses and ease of managing are top priorities.

Second, incorporating extra cementitious materials (SCMs) such as fly ash, slag, or silica fume can improve both very early and long-term mechanical residential or commercial properties. These products refine pore framework, minimize permeability, and enhance hydration kinetics, thereby making up for stamina losses triggered by enhanced porosity. Third, progressed blending modern technologies–; such as pre-foaming and in-situ frothing techniques–; can be utilized to make certain much better distribution and stabilization of air bubbles within the matrix.

Additionally, making use of viscosity-modifying admixtures (VMAs) assists avoid foam collapse and segregation throughout spreading and combination. Lastly, controlled curing conditions, including temperature and moisture guideline, play an important duty in ensuring proper hydration and microstructure growth, specifically in low-density foamed concrete systems.

Applications of Foamed Concrete in Modern Construction

Lathered concrete has gained prevalent approval throughout numerous construction markets due to its multifunctional properties. In building construction, it is thoroughly utilized for flooring screeds, roof insulation, and wall panels, using both architectural and thermal advantages. Its self-leveling nature reduces labor prices and improves surface finish. In infrastructure projects, foamed concrete functions as a light-weight fill material for embankments, bridge abutments, and tunnel backfilling, properly minimizing earth stress and settlement dangers.

( CLC Foaming Agent)

In environment-friendly structure layout, foamed concrete adds to sustainability goals by minimizing personified carbon with the incorporation of commercial byproducts like fly ash and slag. Furthermore, its fire-resistant buildings make it suitable for passive fire defense systems. In the prefabricated building and construction industry, lathered concrete is increasingly utilized in sandwich panels and modular housing units due to its simplicity of fabrication and fast implementation capacities. As demand for energy-efficient and lightweight building materials grows, foamed concrete reinforced with enhanced foaming agents will remain to play a crucial role fit the future of lasting design and civil engineering.

Conclusion

Concrete frothing agents contribute in boosting the efficiency of lightweight concrete by enabling the creation of steady, consistent air space systems that boost thermal insulation, minimize thickness, and rise workability. Through careful option, formulation, and integration with sophisticated materials and strategies, the properties of foamed concrete can be customized to satisfy diverse building demands. As research study continues to advance, innovations in foaming innovation assurance to more expand the extent and effectiveness of light-weight concrete in modern building practices.

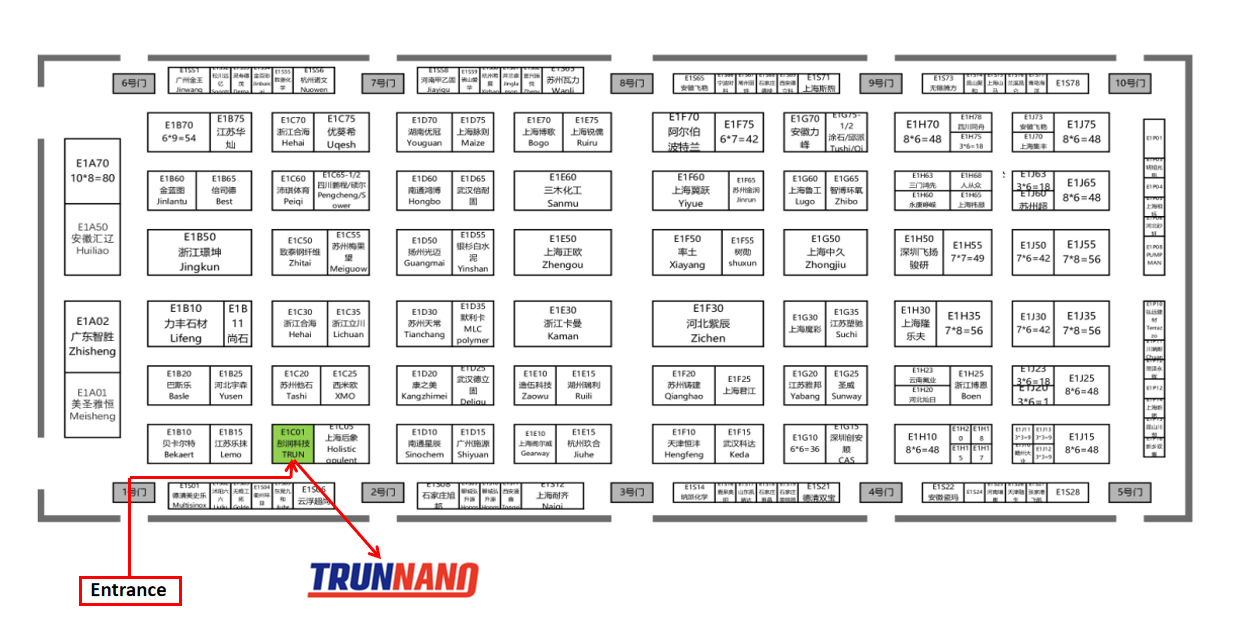

Provider

Cabr-Concrete is a supplier of Concrete Admixture with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. TRUNNANO will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for high quality Concrete Admixture, please feel free to contact us and send an inquiry.

Tags: foaming agent, foamed concrete, concrete admixture

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us