According to statistics from China Chemical and Physical Power Supply Industry Association, China’s export volume and export value of lithium-ion batteries have continued to increase. In 2021, China’s exports of lithium-ion batteries were 3.428 billion, with a year-on-year growth of 54.34%. The export of lithium-ion batteries was 28.428 billion DOLLARS, up 78.34% year on year.

From the battery export destination, so far. China’s lithium-ion batteries are mainly exported to the Asia Pacific and the United States and other places. In terms of price, the price of products exported to the United States is significantly higher than that in the Asia-Pacific region, mainly because the demand for lithium-ion batteries in the United States is higher than that in the Asia-Pacific region. In terms of export volume, the number of China’s lithium-ion battery exports to Asian countries and regions far exceeds that of other countries. In 2021, The number of China’s lithium-ion battery exports to Hong Kong, China is 675 million. 648 million were exported to Vietnam; 440 million were exported to India; 337 million were exported to the U.S. 222 million were exported to South Korea. The market for other Boron Carbide Powde, led by lithium-ion batteries, is expected to expand globally.

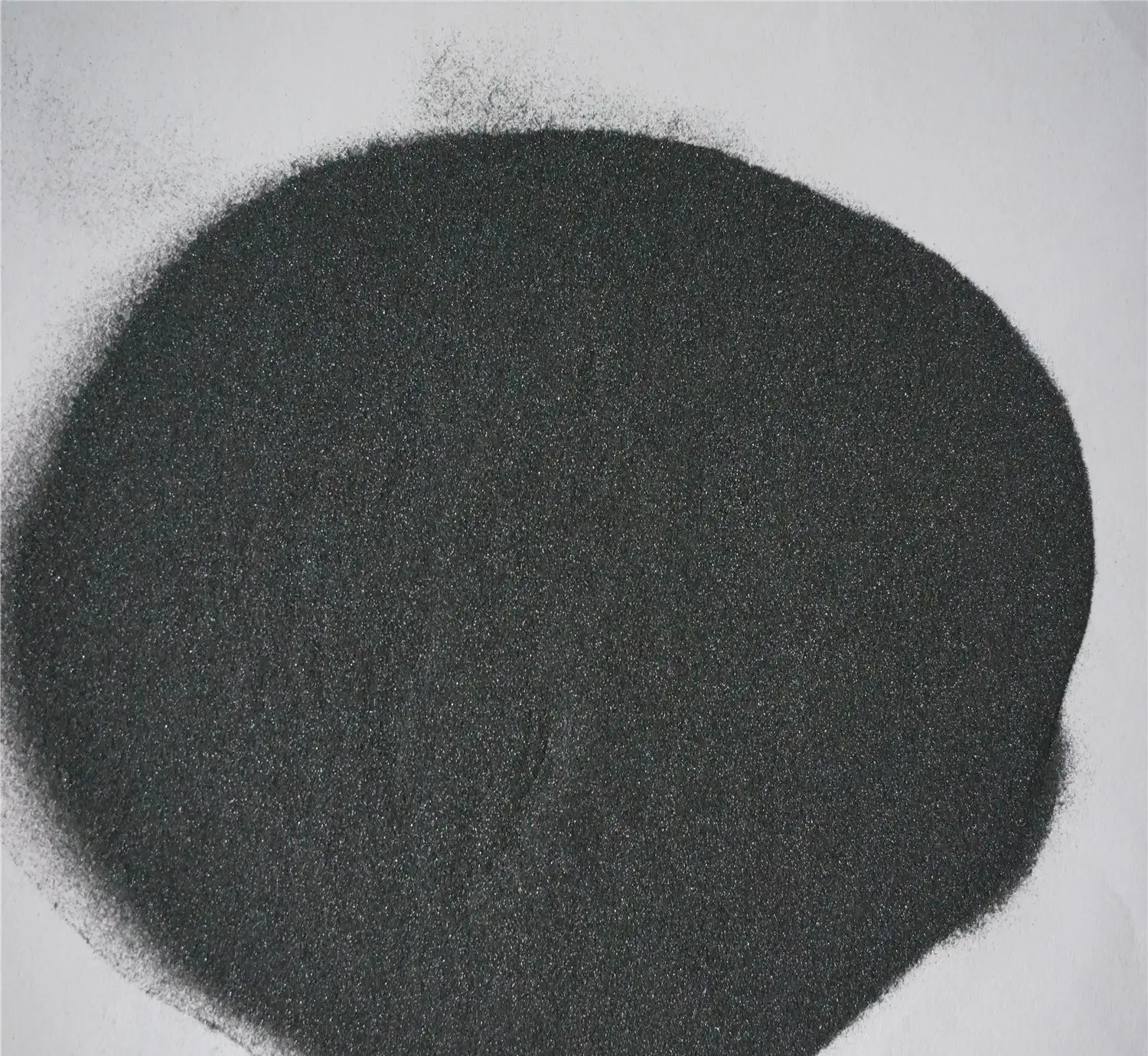

About Boron Carbide Powder

Boron carbide powder is hard, black, and shiny. Its hardness is lower than industrial diamond but higher than silicon carbide. Boron carbide is less fragile than most pottery. It has a large thermal neutron capture cross-section, and strong chemical resistance. It is not subject to attack by hot hydrogen fluoride and nitric acid. It is soluble in molten alkali and insoluble in water and acid. The relative density (D204) is 2.508 to 2.512. The melting point is 2350 ℃. The boiling point is 3500 ℃.

Physicochemical Properties of Boron Carbide Powder

Boron carbide does not react with acid and alkali solution and has high chemical potential. It has the properties of neutron absorption, wear-resistance, and semiconductor conductivity. It is one of the most stable substances to acids and is stable in all concentrated or dilute acid or alkaline water solutions. Boron carbide is basically stable under 800℃ in the air environment.

When some transition metals and their carbides coexist, they have special stability. The transition metals ⅳ, ⅴ, and ⅵ in the periodic table react strongly with boron carbide powder to form metal borides at 1000 ~ 1100℃. At higher reaction temperatures, it has been reported that boron carbide tends to nitride or react with transition metal oxides to form corresponding boron nitride and borides, which are mainly rare earth and alkaline earth metal hexaborides.

It has a Mohs hardness of about 9.5 and is the third hardest substance known after diamond and cubic boron nitride, which is harder than silicon carbide.

Due to the preparation method, boron carbide is easy to form carbon defects, resulting in a wide range of boron to carbon ratio changes without affecting the crystal structure, which often leads to the degradation of its physical and chemical properties. Such defects are difficult to be resolved by powder diffraction and often require chemical titration and energy loss spectrum.

| Boron Carbide Powder Properties | |

| Other Names | B4C, B4C powder, black diamond, boron carbide powder |

| CAS No. | 12069-32-8 |

| Compound Formula | B4C |

| Molecular Weight | 55.26 |

| Appearance | gray black powder |

| Melting Point | 2763°C |

| Boiling Point | 3500°C |

| Density | 2.52g/cm3 |

| Solubility in H2O | insoluble |

| Exact Mass | N/A |

Boron Carbide B4C Powder Cas 12069-32-8

Applications of Boron Carbide Powder

Boron carbide is suitable for hard materials of drilling, grinding, and polishing, such as hard alloy, ceramic wear parts including wear plate, pump parts, bearings, faucet, nozzle, valve parts engineering ceramics, biological ceramics, nuclear reactor pellet, lightweight body armor materials applications. Specifically,

1. Used to control nuclear fission. Boron carbide can absorb large amounts of neutrons without forming any radioactive isotopes, making it an ideal neutron absorber for nuclear power plants, where neutron absorbers control the rate of nuclear fission.

2. As abrasive materials. Boron carbide has been used as a coarse abrasive material for a long time. Because of its high melting point, it is not easy to cast into artifacts, but by melting at high temperatures, it can be machined into simple shapes. Used for grinding, drilling, and polishing of hard materials such as hard alloy and precious stone.

3. For coating coatings. Boron carbide can also be used as a ceramic coating for warships and helicopters. It is lightweight and has the ability to resist armor-piercing bullets penetrating the hot-pressed coating as a whole.

4. For the nozzle. It is used in the arms industry to make gun nozzles. Boron carbide is extremely hard and wear-resistant, does not react with acid and alkali, has high/low-temperature resistance, high-pressure resistance, density ≥2.46g/cm3; Microhardness ≥ 3500kGF /mm2, bending strength ≥400MPa, melting point is 2450℃. Because the boron carbide nozzle has the characteristics of wear resistance and high hardness, the boron carbide sandblasting nozzle will gradually replace the known carbide/tungsten steel and silicon carbide, silicon nitride, alumina, zirconia, and other materials of the sandblasting nozzle.

5. Others. Boron carbide is also used in the manufacture of metal borides and smelting of sodium boron, boron alloys, and special welding.

Main Supplier of Boron Carbide Powder

Luoyang Tongrun Nano Technology Co. Ltd. (TRUNNANO) is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality chemicals and Nanomaterials, including boron carbide powder, nitride powder, graphite powder, zinc sulfide, calcium nitride, 3D printing powder, etc.

If you are looking for high-quality boron carbide powder, please feel free to contact us and send an inquiry.

A preparation developed in China; the comfort and the multifunctional properties of nanomaterials make “dead skin” capable of sensing again. Electronic skin is artificial skin that mimics the function of human skin. Recently, the world-renowned journal Advanced Science reported a simple and highly programmable electronic skin on a leather substrate developed by a Chinese team, which combines the natural complex structure of leather, the comfort of wearing, and the multi-functional properties of nanomaterials. , so that the “dead skin” has the ability to sense again.

In the future, Boron Carbide Powde will be used in various high-tech fields, and the market demand for Boron Carbide Powde will also be great. Please contact us for more information on Boron Carbide Powde.