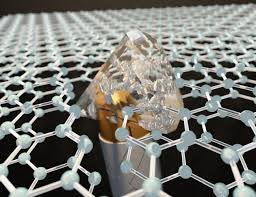

Graphene, a two-dimensional material with unique properties, has been the subject of much attention in recent years due to its potential applications in various fields such as electronics, energy storage, and medicine. However, how graphene is made remains a topic of intrigue and debate among scientists.

(how graphene sheet is made)

The process of making graphene involves. Graphene can be synthesized through a method called chemical vapor deposition (CVD), which involves heating a carbon-rich gas to high temperatures and allowing it to flow into a substrate where it can bond with other materials.

CVD is an industrial process that has become increasingly popular in recent years due to its ability to produce high-quality graphene at lower cost than traditional methods. The first step in CVD is to introduce carbon atoms into a gas chamber using a vacuum source. The carbon atoms are heated to a temperature of around 3,500°C and then collide with the substrate at high speeds. This causes the carbon atoms to stick together and form a network of interconnected layers, resulting in a layer-by-layer buildup of graphene.

Another important step in the production of graphene is to remove impurities from the surface of the graphene sheet. This is typically done using a technique called mechanical exfoliation, which involves removing layers of graphene by physically shaking or rubbing them away.

Once the graphene sheet has been synthesized and processed, its properties can be tuned by adjusting various factors such as the purity of the carbon atoms, the thickness of the graphene sheet, and the method used to introduce the carbon atoms.

One of the most exciting aspects of graphene’s properties is its ability to conduct electricity and heat with very high efficiency. This is because the electrons in graphene have such low mobility, which allows them to move through the material easily without resistance. Additionally, graphene’s strong bonding between carbon atoms makes it resistant to environmental damage, which means that it can be used in a wide range of applications without suffering degradation.

(how graphene sheet is made)

Overall, while the process of making graphene may seem daunting at first glance, there are many different ways in which it can be synthesized and processed to meet specific requirements. As researchers continue to explore new synthesis methods and improve upon existing ones, we can expect to see even more innovative uses of graphene in the future.