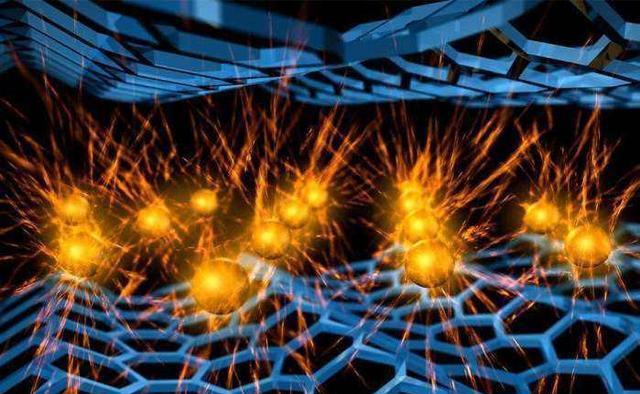

Graphene, a material with incredible properties, has gained significant attention in recent years due to its unique electronic and mechanical characteristics. It is believed that the unique structure of graphene, which consists of layers of carbon atoms arranged in a hexagonal lattice, allows it to have a number of unique properties, such as high strength, conductivity, and thermal stability.

(how is graphene made)

The process of making graphene involves several steps. The first step is to grow graphene on a surface, typically using techniques such as chemical vapor deposition (CVD) or mechanical exfoliation. Once the graphene is grown, it must be purified and chemically treated to remove impurities and achieve the desired purity level.

In addition to growing graphene on a surface, other methods can also be used to produce graphene, including the use of metal-organic frameworks (MOFs) and quantum dots. These methods involve creating structures with specific geometries that allow for the controlled growth of graphene.

Once graphene is produced, it must be characterized to determine its physical and electrical properties. This involves using a variety of techniques, such as X-ray diffraction (XRD), transmission electron microscopy (TEM), and scanning tunneling microscopy (STM).

One of the most important applications of graphene is in the field of electronics. Graphene’s exceptional electronic properties make it an ideal material for use in electronic devices, such as solar cells and transistors. Its high electrical conductivity makes it particularly useful for charge transport in electronic circuits, while its strong magnetic properties make it suitable for use in magnetic sensors.

In addition to its potential applications in electronics, graphene has also been studied for its potential use in energy storage and fuel cells. Graphene’s high thermal conductivity and good energy storage capacity make it a promising material for use in batteries and fuel cells.

Despite the many potential uses of graphene, there are still many challenges that need to be overcome before it can become a widely used material. One of the biggest challenges is improving the quality and purity of graphene, which requires advanced techniques and specialized equipment. Another challenge is developing new methods for manufacturing graphene that can efficiently scale up to meet the demand for the material.

(how is graphene made)

Overall, while graphene has yet to reach widespread adoption as a material, its unique properties and potential applications make it a promising technology with great potential for the future. With continued research and development, it is likely that graphene will play an increasingly important role in the development of new materials and technologies.

Inquiry us