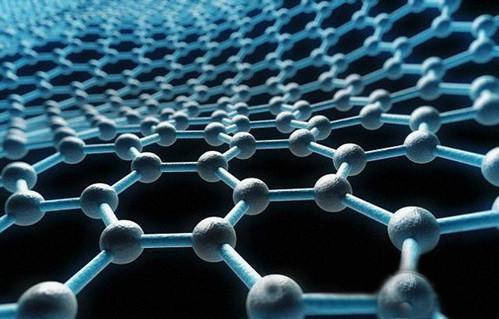

Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, is one of the most promising materials for use in various technological applications due to its unique properties such as high electrical conductivity, thermal conductivity, and mechanical strength. However, despite its numerous benefits, the cost of graphene production remains relatively high.

(how much does graphene cost per sheet)

The cost of graphene depends on several factors such as the quality of the raw materials used, the equipment and processes involved in producing the material, and the scale of production. According to market research firm MarketsandMarkets, the global graphene market size was valued at $1.7 billion in 2019 and is expected to reach $3.6 billion by 2024, growing at a CAGR of 8.5% during the forecast period.

One of the main reasons for the high cost of graphene is the complexity of the manufacturing process. Graphene can be produced using two different methods: chemical vapor deposition (CVD) and mechanical exfoliation. CVD involves the application of a gas mixture containing carbon precursors to create graphene by depositing layers of graphene on a substrate. On the other hand, mechanical exfoliation involves breaking down graphene into individual sheets through physical forces.

Both methods require specialized equipment and sophisticated processes, which makes them expensive. For example, CVD requires highly advanced vacuum systems, which can be costly to build and maintain. Mechanical exfoliation, on the other hand, requires powerful tools such as milling machines, which can be expensive to purchase.

Another factor that contributes to the high cost of graphene is the availability of raw materials. The cost of graphene depends heavily on the quality and purity of the raw materials used in the production process. Carbon substrates are the primary raw material used in both CVD and mechanical exfoliation. Therefore, if the cost of carbon substrates increases, the cost of graphene will also increase.

Moreover, the scaling up of production to meet the increasing demand for graphene is another factor that drives up the cost of the material. As more companies invest in graphene production, the competition for supplies will intensify, leading to higher costs for everyone.

(how much does graphene cost per sheet)

In conclusion, while graphene has enormous potential in various technological applications, its high cost remains a significant barrier to widespread adoption. To overcome this obstacle, researchers and industry players need to work together to develop more efficient and affordable manufacturing methods for graphene. Additionally, policies that encourage the development of low-cost graphene technologies should be implemented to ensure that everyone has access to this innovative material.